Smooth Moves: Sand's Impact on Surface Finish

- Hill and Griffith

- Dec 22, 2019

- 4 min read

Different Types of Sand Molds and Cores Used by Your Supplier Will Impact the Surface Finish of Your Castings.

Excerpt from Casting Source Magazine Jan/Feb 2016 issue

For many casting buyers, a smooth, uniform surface finish is more than a visually appealing bonus. It can be a sign that the casting supplier has produced a high-quality component. Perhaps more importantly for the casting buyer, a proper surface finish can lead to eventual cost savings in the cleaning, finishing and machining of the part.

Castings produced in sand molds can have relatively smooth surfaces, but if need be, the baseline surface finish can be improved through various means, though such gains will come with additional costs. Discussions with casting suppliers can help buyers understand potential solutions and associated costs.

Sand Selection & Other Variables

The surface finish of your cast components depends greatly on the type and quality of sand used in the casting process. The sand’s manipulation and makeup are vital considerations. Your potential supplier invests time, money and effort in ensuring these materials are being used to their greatest potential.

The method of compaction in sand molding influences surface finish at all levels. Sand grains that are packed tightly produce a more uniform surface over which molten metal will eventually flow, mimicking the appearance of the sand itself. Hand ramming makes for the worst compaction. Blowing produces a smoother surface than hand ramming, while the jolt-squeeze method provides an even smoother, more compact mold than blowing. Automatic molding machines also generate superior surfaces.

Sand makes up a large majority of the casting mold, and it has an equally significant impact on the casting’s eventual surface finish.

In all of the bonded sand processes, the finer the sand grains in use at your supplier’s metalcasting facility, the smoother the surface finish you will see. Larger grains produce larger peaks and valleys as molten metal flows into the spaces between them. Those peaks and valleys, generally measured in microns, produce a roughness value—root mean squared (RMS)—where small numbers mean a slick finish.

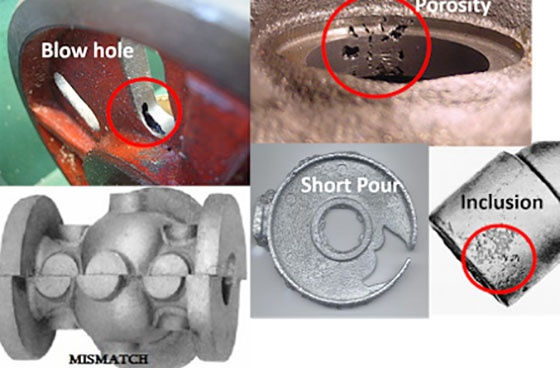

Smaller grains sit more closely to one another to produce that smooth surface finish, but they also will produce a less permeable mold, trapping gases within that would have seeped out of more porous sands. This can cause porosity and other gas defects in the finished casting.

The surface area of the sand used also increases with finer grains. This too presents a trade-off—more resin is required to coat the sand mixture when the surface area is increased. This can equate to a rise in cost that may be passed on to the buyer.

Resins and coatings can improve casting surface quality with the use of almost any type of sand. Resins, such as phenolic urethane, can smooth out casting surfaces and provide some refractory properties. Generally, resin-coated sands are used for applications that require exceptional surface finish.

Shell sands produce some of the best surface finishes in the sand casting arena because they tend to combine the highest hot strength and resin level with the finest grain of any chemical sand.

Lower cost sand also includes more impurities, including foreign elements that compromise the flowability of the sand. To combat these contaminants, which can change the way region-specific sand compacts, metalcasters can use a coating that fills in the gaps that result on the mold and core faces. Such a coating will cause particles to be transferred to the surface via a zircon conductor. Of course, this means moving toward materials that are harder to source.

Considerations During Casting

Even if you know what kind of surface finish you require, how do you find the right metalcaster to deliver it?

According to Jiten Shah, president, Product Development & Analysis LLC (PDA), Naperville, Ill., the values published in Figure 1 and Table 1 are drawn from a random sample of metalcasting facilities in the U.S. and abroad. PDA collected published capabilities from the participating metalcasting facilities and used them to create an average range. The extreme values are based on the lowest root mean square (RMS) in micro-inches values the company discovered published in the literature.

You can use the published values to zero in on the appropriate process, but the next challenge is figuring out who falls where on the provided spectrum. You’ll also likely have to pay for the surface finish improvements available in certain processes. The no-bake process is more expensive than green sand, but the resulting surface finish is generally improved.

As an alternative to changing processes, you can work with your metalcaster to see which finishing processes might be available to improve the final surface of your component. The cast component producer may be able to use a different shot blast material, such as glass beads, to smooth a rough surface. Machining certain surfaces might also present an economically viable alternative.

Shah said a metalcasting facility can achieve the lower end of the surface finish range—and even those extreme best-case surface finishes—by controlling several factors: weight/section thickness, alloy and mold material treatment.

The first two are straightforward. As weight and section thickness increase, the quality of the surface finish decreases. And alloys with higher melting points produce lower RMS values than alloys with lower melting points. In other words, iron castings will not be as smooth as aluminum castings, and steel castings typically will be rougher still. According to the data gathered by Shah, aluminum can be cast to lower surface finishes than can iron. Copper falls somewhere in between those two materials. The same is true for nonferrous alloys versus ferrous alloys in the shell molding process.

Sand preparation is the foremost concern when trying to limit roughness, but metalcasters must address the molten metal’s entry into a mold. Aside from achieving a metallurgically sound melt prior to pouring, casting suppliers should be wary of extremely high temperatures when trying to smooth out their surfaces. Radiant heat from the molten metal can lead to degradation of the mold surface, which can produce conditions that lead to poor surface finish.

Mold faces also can be compromised when liquid metal physically crashes into the sand. Increased turbulence in the melt can cause imperfections in the sand mold, which can lead to flaws in the casting’s surface.

More News from Casting Source Magazine

Comments